Kraftværker / Voimalaitokset / Powerplants / 発電所 / Centrali elettriche

Beauties hidden behind inconspicuous facades. Insights into power plants and their production processes. Unique architecture, both still analog and ultra-modern technologies built into huge halls without which our rooms would remain dark...

Under Impressions from power plants you will find some albums of power plants.

Preservation of history

Without the thermal power plants, the modern life we live today, with all its comforts, would not be possible.

In order to never forget what was once the beginning of everything, it is extremely important to keep a record of the history of electricity generation. Every power station is unique. A journey into another time, often still characterized by analog technology. The architecture, the attention to detail and the components used will never be the same again.

Everything that is not preserved disappears quietly and unseen, yet it is these structures in particular that have made it possible for us to live in the first place.

Explanation of the operating principle

Below you can take a look at some of the important components of a hard coal-fired power plant. Lignite-fired power plants are largely similar in design, but there are small differences, for example in terms of coal processing, as they have a different degree of hardness and moisture compared to hard coal.

All the effort - from coal extraction, transportation, crushing to finally combustion and complex flue gas cleaning, so that the shaft of the turbine turns at a constant 3000 rpm (revolutions per minute) and we can obtain electrical energy from the generator.

The exact 3000 rpm revolutions are extremely important for our power grid to keep it at 50Hz. If we were to feed in at a different frequency, we would affect the entire connected power grid. If the frequency exceeds or falls below 50Hz, a system failure is possible as almost all devices are set to 50Hz. However, there is a minimum tolerance.

For further grid stabilization Phase shifters, for example, are beeing used.

A high level of concentration is required during monitoring to ensure a smooth production process.

The difference can be clearly seen in the number of buttons...

Many German hard coal-fired power plants source their raw materials from countries such as Canada, Colombia, South America and the USA. After hard coal production in Germany was finally discontinued on December 21, 2018, imports are the only way to obtain this raw material.

As a rule, the coal is always transported by ship to or near the respective power plants. These are then unloaded using excavators, sometimes in an automated process. The coal remains in the coal store or coal bunker until it is burned.

In the case of lignite-fired power plants, delivery is often somewhat simpler as these are usually located near an open-cast mine. Transport from the open-cast mine to the power plant is carried out either by conveyor belts or by train.

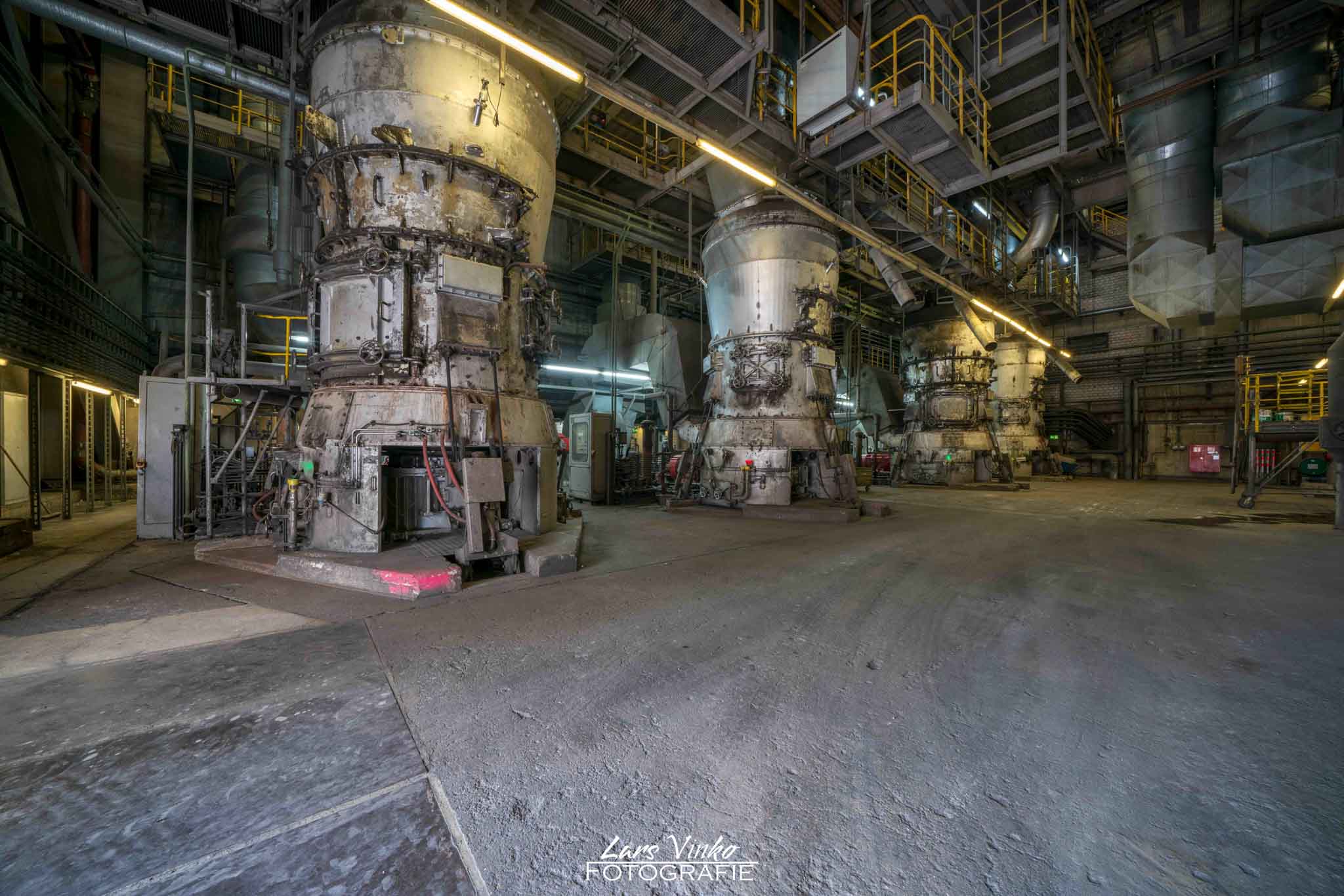

If the coal is required for the combustion process, it is fed into the coal mills (vertical mills are shown here) in which the coal is dried by the exhaust gases from combustion or other firing systems and finely ground. The fine coal powder then reaches the injectors/burners.

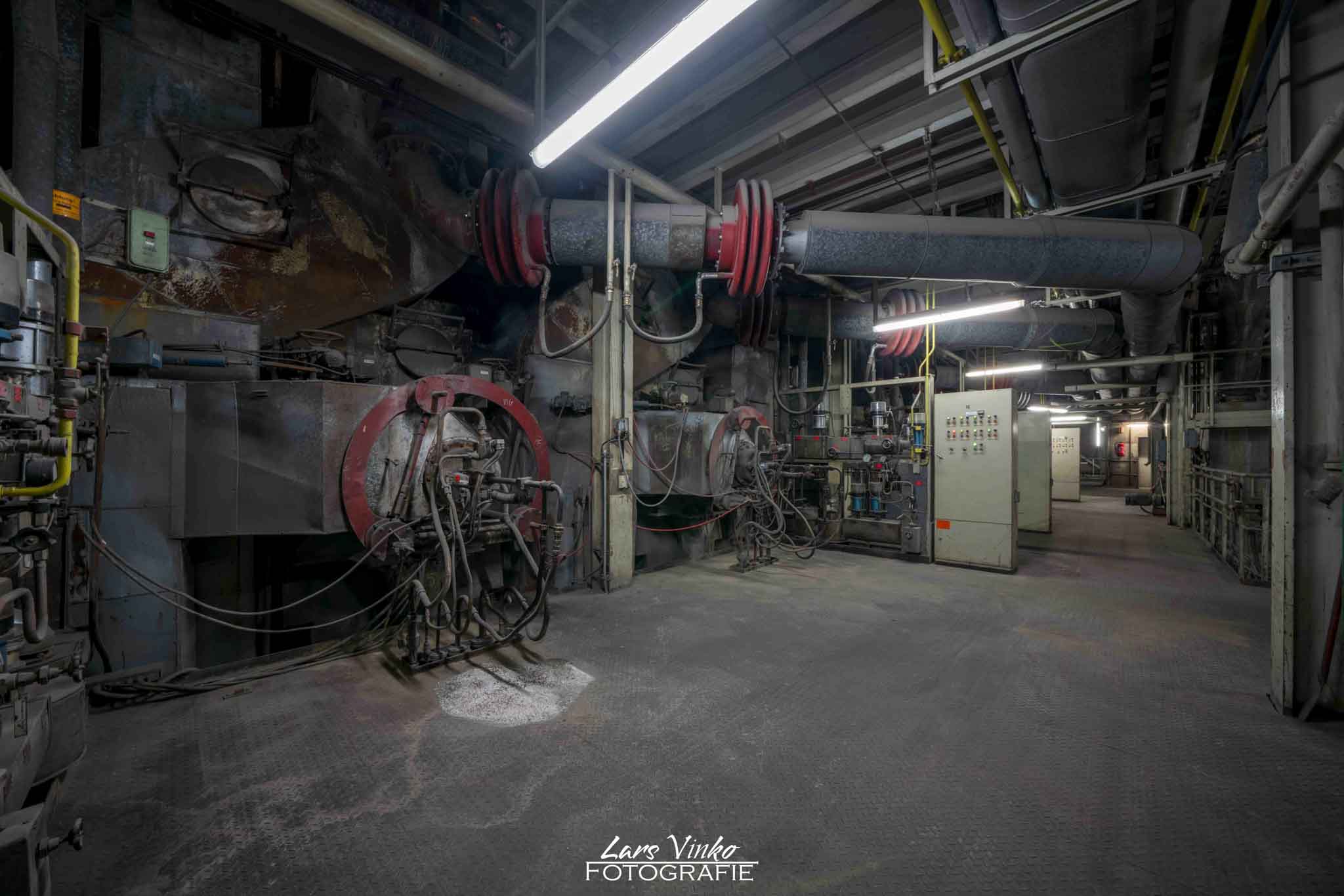

When the boiler is "up to temperature" (e.g. during a cold start, it is first preheated with heavy fuel oil or other fuels), the coal dust is blown into the boiler via the injectors/burners, which immediately starts to burn. Depending on the size of the boiler, a large number of such burners can be installed. Most of the power plants I have visited had 12-16 burners each, spread over several levels.

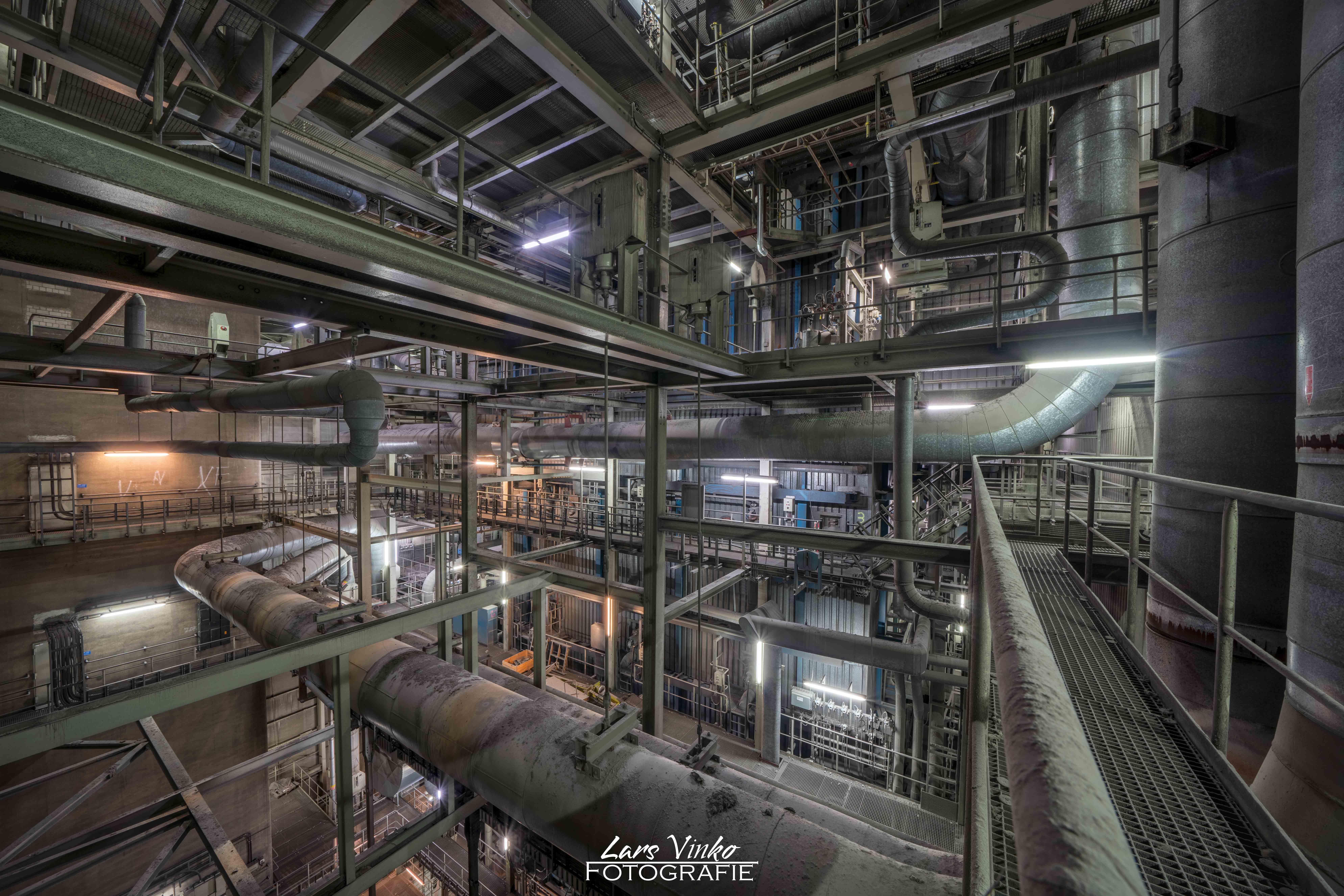

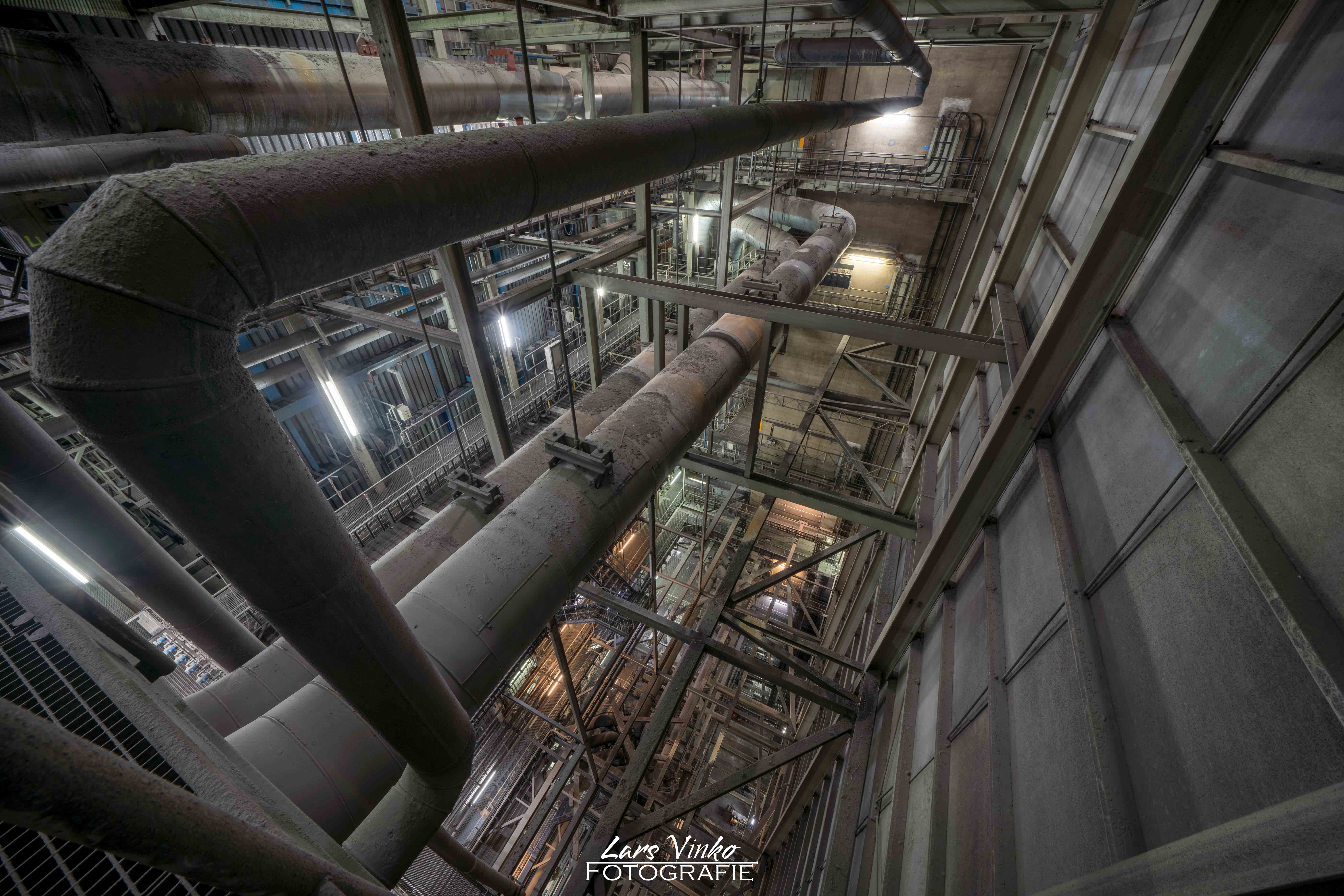

The boiler

Possibly also referred to as the "heart" of the power plant, because without a boiler, there is no steam for the turbine. However, we burn raw materials to convert their thermal energy into kinetic and then electrical energy. It's best to decide for yourself which is the heart...

The structure of a boiler is quite simple; in addition to huge supports to which the boiler is attached (due to the expansion of the boiler during heating), there are many kilometers of piping for water on the inside wall of the boiler. The feed water is heated in these pipes and the resulting steam is transferred under high pressure to the steam turbine.

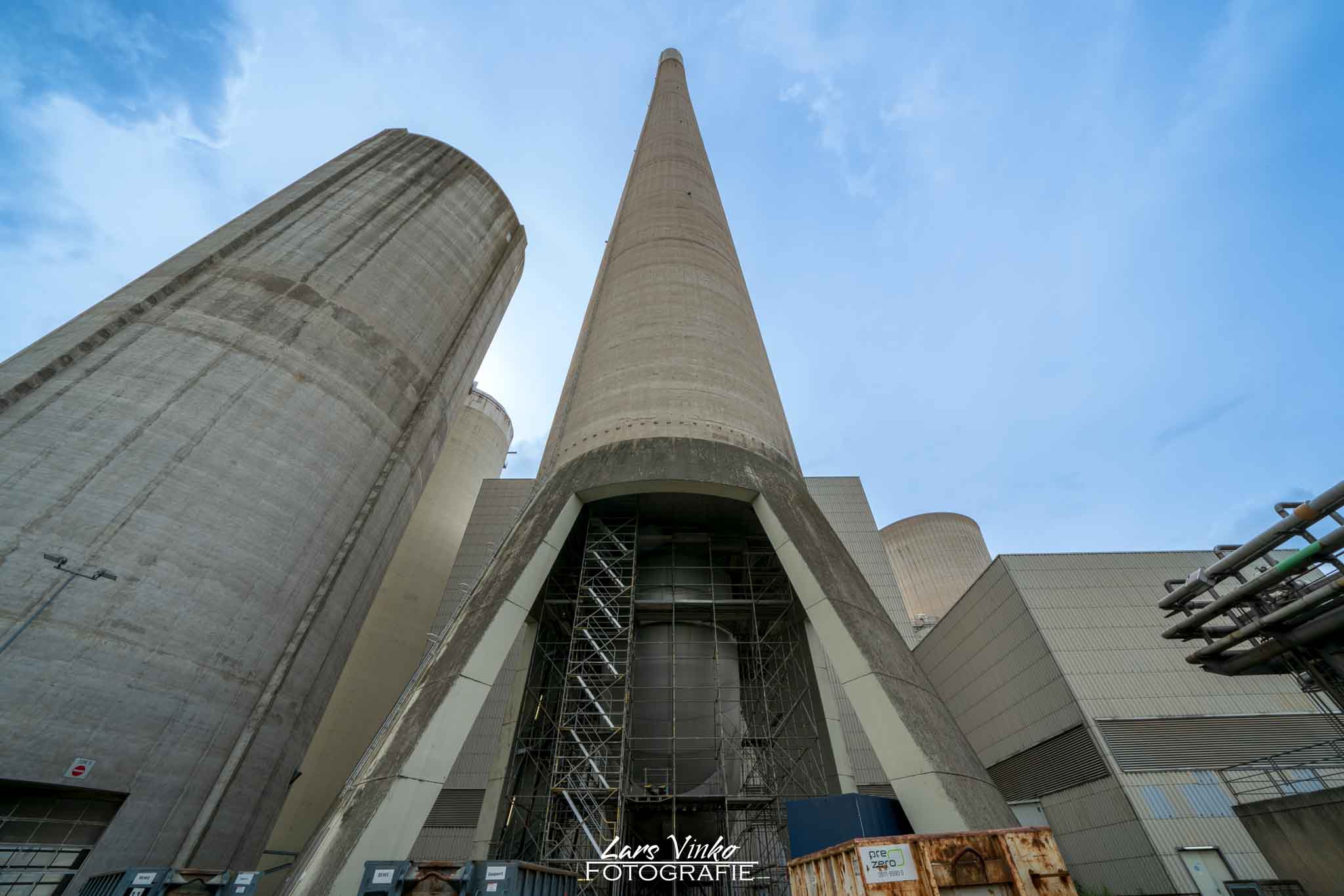

With their remarkable size and height, these boilers are truly impressive. The tallest boilers, which are also the tallest industrial buildings in Germany, are located in Neurath (North Rhine-Westphalia) and stand at an impressive 173 meters (Neurath power plant, blocks F & G).

These have the task of supplying the boiler with sufficient feed water, which is required to generate steam.

In steam power plants, they are usually found as centrifugal pumps. In larger power plants, a backing pump is also installed upstream to provide the necessary inlet pressure.

The feed pumps are usually driven by a smaller steam turbine. This turbine also receives the steam from the power plant's main steam boiler. Electric feed pumps are used for the start-up and shut-down process as the steam supply for the drive turbine is not sufficient at these times.

These large pieces of equipment are located below the steam turbine. After the steam has passed through the turbine blades, it loses a lot of energy and slowly begins to condense again. The condensed steam is collected here and added back to the cycle after a certain amount of cooling.

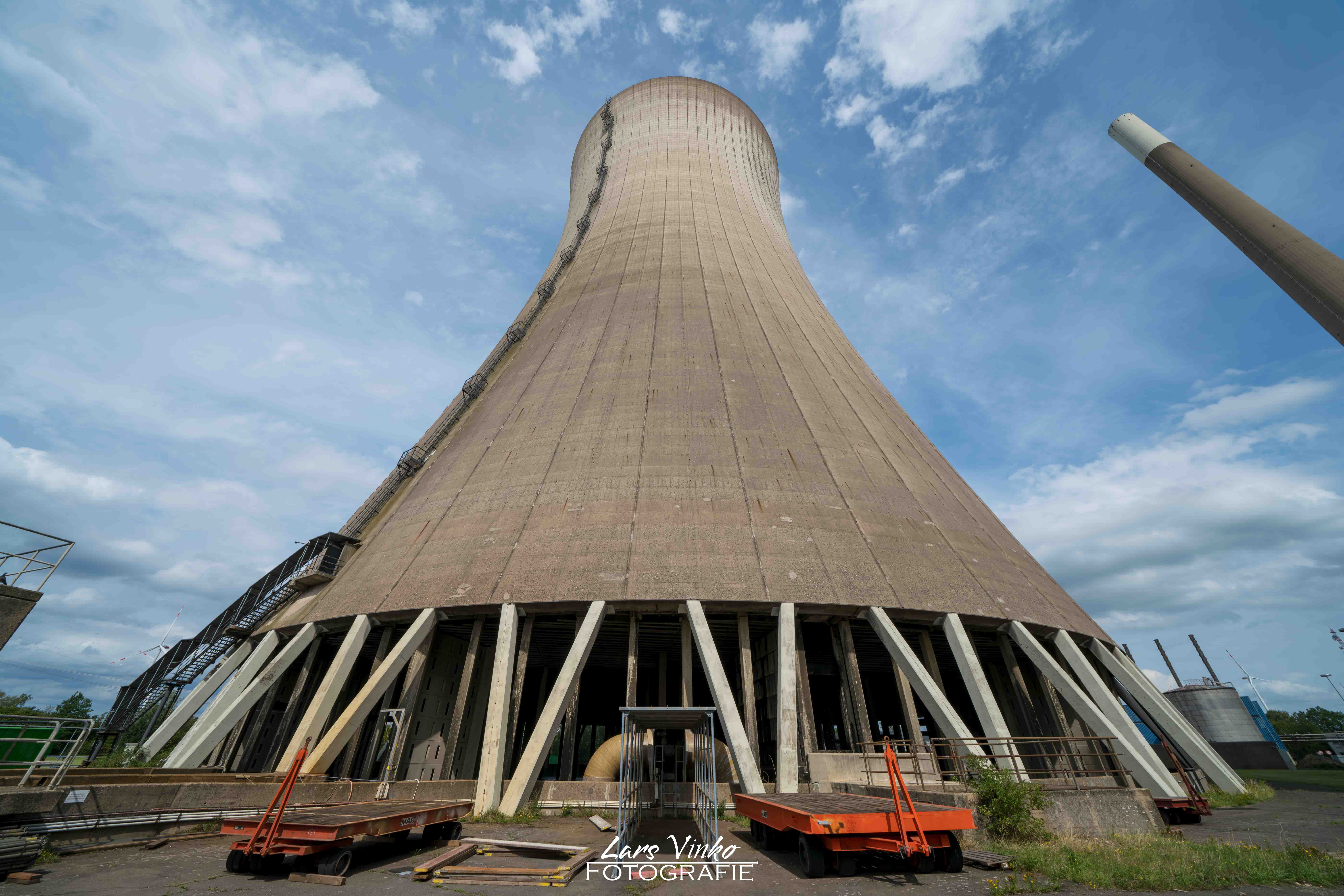

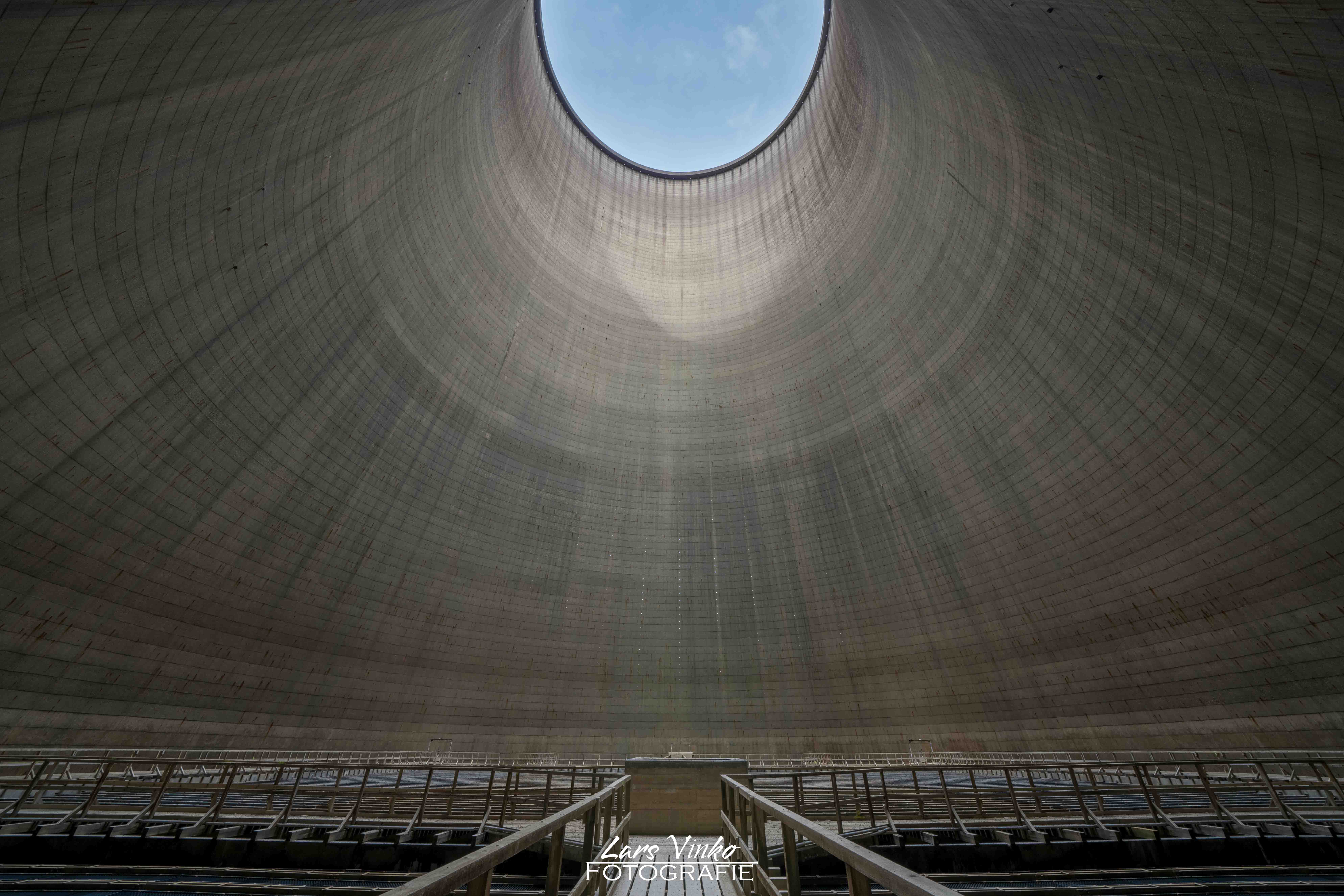

The cooling tower

Like the symbol of a large power plant. Most people associate tall cooling towers and their dense white clouds of steam with high pollutant emissions. However, these clouds usually contain only H2O—in other words, water. This depends, however, on whether there is a separate chimney for pollutants. Otherwise, these are discharged via the cooling tower.

The purpose of the cooling tower is to further cool the steam that has not yet condensed and to collect as much of the condensate as possible. This is then returned to the cycle.

The tallest cooling tower in the world at the time of its construction is located in Niederaußem (NRW) and belongs to the BoA (lignite-fired power plant with optimized plant technology) Block K.

FGD (flue gas desulphurization plant) / flue gas cleaning

As the title suggests, the flue gases from the combustion in the boiler are cleaned of sulphur oxides in these systems. Please note that a FGD is only one part of the overall flue gas cleaning process!

Specifically, in the wet process used in FGD, sulfur oxides are filtered out of the flue gas by more than 95% through the addition of certain absorbents (limestone suspensions are widely used). The unpurified flue gas is sprayed with a mixture of limestone and water (washing suspension) in a washing tower (absorber tower), whereby the sulfur dioxide is largely bound by chemical reaction. After several chemical reactions, plaster ultimately forms in a suspension. This suspension is then dried and the resulting plaster is sold as a building material.

We were able to filter out a lot of the flue gases thanks to e-filters and FGD. All fine dusts and, for example, sulphur oxides are not released into the environment. However, it is unfortunately not possible to clean the flue gases 100%. Small quantities are still released, but these are subject to strict guidelines in Germany and are monitored 24/7 without exception. All emissions are reported to the authorities at the same time and sensitive penalties are imposed if the limit values are exceeded.

When asked why some chimneys are built so high: Chimneys of large industrial plants are often built over 200m high to improve the so-called "chimney effect" and better distribute the pollutants emitted.

The era of coal-fired power plants is coming to an end, and I'm sure everyone has their own opinion on whether this decision is good or bad. But regardless of this, we should all remember the important role these particular industrial buildings play and what they have meant for our modern lives as well as in the past. We should never forget what made us what we are today.

Technical masterpieces in all areas brought us these magnificent structures and enabled us to live a better life.

Thanks to all the power plant workers who ensure that we are always supplied with electrical energy at any time of the day or night.